TOGETHER,

Feature Projects

BULLMOOSE-RUTH

Remediation Project

85 km east of Yellowknife, Northwest Territories

2016-2018

Project overview:

The 7 abandoned former mine sites of Bullmoose, Ruth, Spectrum, Beaulieu, Joon, Chipp, and Storm are collectively referred to as the Bullmoose-Ruth Area Mine Sites. The remediation project included constructing a landfill at Bullmoose and a landfill at Ruth, transporting hazardous waste off-site for disposal, transporting waste from the remote sites to the Bullmoose landfill, sealing mine openings with concrete seals, sealing mine openings with PUF foam, demolishing abandoned structures, quarry development, earthworks, treatment of hydrocarbon-impacted soil, sediment remediation, Bullmoose Creek reconstruction, and two seasons of constructing over 130 kms of winter road to access the sites.

Scope:

FORWARD Mining partners Rowe’s and Outcome successfully completed the site remediation project on budget and one year ahead of schedule. Rowe’s Construction used its fleet to build the winter road, haul material, build the landfills and complete the construction requirements of the remediation project. Outcome provided construction management, scheduling, project controls, design and regulatory compliance outputs.

GREAT SLAVE LAKE AREA MINES

Remediation Project

East Arm Great Slave Lake, Northwest Territories

2014-2015

Project Overview:

The four former mine sites of Outpost Island, Blanchet Island, Wilson Island, and the Waldron River Property are collectively known as the GSL Area Mine sites. The remediation project included accessing the remote sites by barge, earthworks, sealing mine openings, transporting hazardous waste off-site for disposal, concrete demolition, excavation and off-site disposal of metal-impacted soils and debris from Outpost Island, and construction of a containment cell at Blanchet Island.

Scope:

FORWARD Mining partner Rowe’s Construction was awarded the remediation contract. The successful completion included using the Rowe’s barge to access the GSL sites and Rowe’s equipment to complete the construction work including sealing mine openings, earthworks, and building a lined containment cell at Blanchet. Outcome provided construction management, project controls, and logistics support.

BRUCEJACK MINE

Mine Development Project

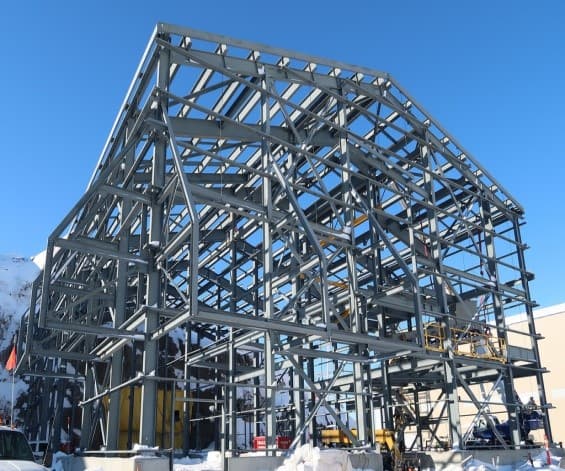

Mill Building Internal Steel Erection and Main Camp Steel Erection

2016-2017

Project Overview:

The Brucejack Mine Mill Building and Main Camp steel erection required supply and fabrication, including the engineering and design of all the required connections and all coatings, of all the internal structural and external portal building steel framing, platforms, floor decking, floor grating, stairs, guardrails, and ladders.

Scope:

FORWARD Mining partner Formula Contractors was awarded the supply and fabrication, including the engineering and design. During the period of the Mill Building project Formula managed the supply on an accelerated timeline of approximately 1,800,000 kg of structural steel, 3,800 m2 of grating, 4,400 m2 of elevated deck, 3,500 lm of handrail with kick plate and 254 vm of stairs. The installation of this material was completed primarily with Formula labor and equipment. For the Main Camp, Formula used a 230 crawler crane for the erection of the main camp pad steel grillage.

EAGLE GOLD PROJECT

Mine Development Project

85 km north east of Mayo in central Yukon

2018

Project Overview:

The Eagle Gold mine began construction in 2017 and is estimated to be the largest gold mine in Yukon history. The Eagle gold mine will consist of an open pit operation with a three-stage crushing plant, in-valley heap leach and carbon-in-leach adsorption-desorption gold recovery plant.

Scope:

FORWARD Mining partner Outcome was retained by Pelly Construction Ltd. to provide project planning and controls support for the CC204 Ancillary Earthworks contract, which is one of many related to the development of this new gold mine. Outcome provided planning support through cost estimating, preparing a detailed critical path construction schedule, and preparing a quality management manual, inspection and test plans, and supporting the on-going quality management. Outcome carried out cost and schedule monitoring and prepared progress schedule and lookahead schedule updates during construction, as well as assisting with the change management process.

JERICHO MINE

Remediation Project

Kitikmeot Region – Nunavut

Site Stabilization Project

2017

Project Overview:

The Jericho Site Stabilization project consisted of both environmental remediation and civil construction efforts to stabilize or mitigate residual risks associated with a closed Nunavut diamond mine. The stabilization work including aircraft mobilization logistics from Yellowknife, Northwest Territories, hazardous materials abatement, fuel recovery, tank decommissioning, dam breaches (excavation and blasting), tailings cover and the construction of a containment cell.

Scope:

FORWARD Mining partners Rowe’s and Outcome successfully completed the site stabilization project. Rowe’s Construction provided on-site construction supervision, used its northern logistics experience to expedite the remote project and source equipment suitably sized to fit inside the Hercules aircraft while capable of completing the earth works. Outcome provided construction management, scheduling, project controls, Inuit engagement and hiring as well as regulatory compliance outputs.

Endako Mine Expansion Project

Operational Mine PROJECT

Endako, BC 160 km northwest of Prince George, BC

2011

Project Overview:

The Endako Mine is a surface molybdenum mine located near Fraser Lake, British Columbia. The Endako Mine was a fully integrated facility that began operations in 1965. FORWARD Mining partner Formula Contractors installed cladding, steel structures, and a conveyor as part of the Mine Expansion.

Scope:

FORWARD Mining partner Formula Contractors was retained by Thompson Creek Metals for two projects (Cladding Project and Conveyor Project). Formula installed and cladded the take-up tower, bents and conveyor assemblies in addition to installation of a pre-engineered steel building and annex to the process building. Work also included the installation of canopy, walkway, and all exterior architectural and translucent panels. The conveyor installation project consisted of installation of approximately 350m of conveyor.

Ready to start planning your next mining project?

Give us a call.